SOLUS® Metal Cement is used world wide in all climes.

Productrange

We supply following types:

- SVM

- SVM G

- SMZ

The materials differ in composition with results in viscosity, mechanical strength or semi conduction.

The type of SOLUS® will be especially produced in accordance with the technical demands of the customer.

Application

Application

- Centralisation of grinding wheels

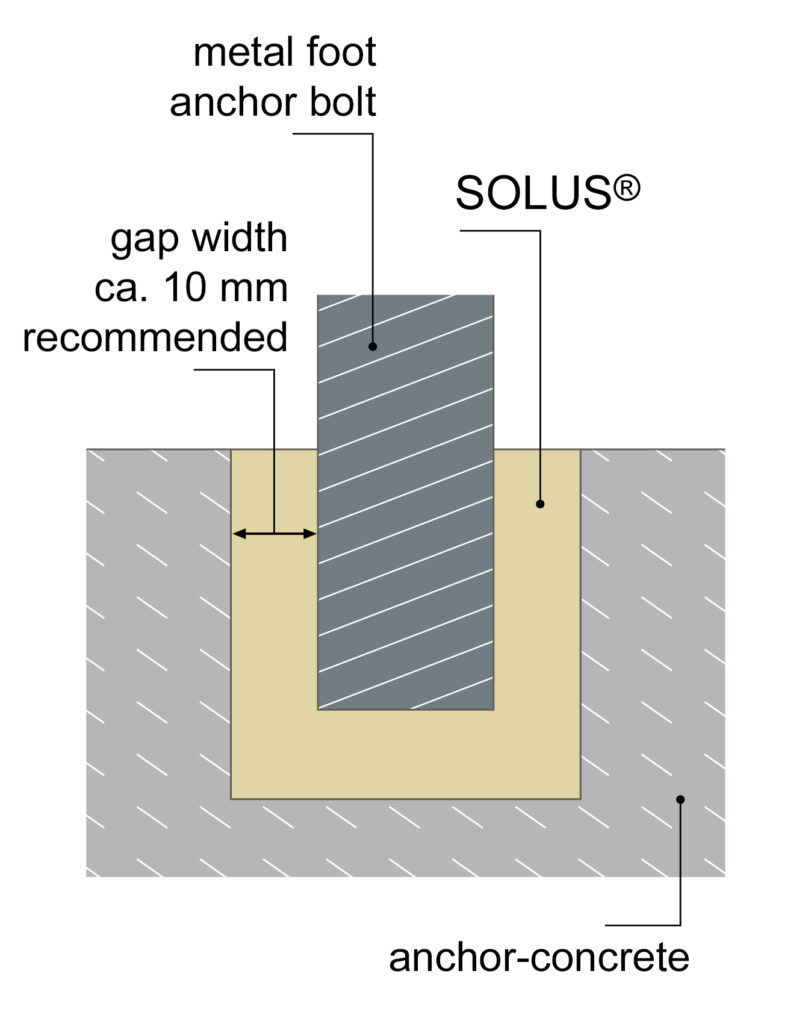

- Fixing and stabilisation of foundations for machines

- rails, balustrades, banisters, protection bars etc

SOLUS® Metal Cement is used for quick fixing especially in concrete.

The fixing is easily to release by warm up the metal parts with a temperature of 120 degree centigrade.

Use and finish same conditions like BASOLIT® – see above

Processing

SOLUS® Metal Cement is supplied ready for use in plates 400 x 400 x 70 mm and a weight of about 18 kg.

Small quantities will be supplied ready for use as fractures (buckets with 10 kg).

SOLUS® should be stored in a dry and clean storage. There is no limit in durability.

SOLUS® has to be melted for use with a temperature between 135 and 145 degree centigrade.

Impact of heat should be smooth from bottom and sides. Continuous stirring should be done, to avoid sedimentation.

Overheating for example from the bottom, leads to a change of viscosity – SOLUS® becomes glutinous, the colour becomes red-brown.

Pouring should be done in two steps shortly after each other. It is necessary to observe, that the temperature is between 135 and 145 degree centigrade, that the SOLUS® is well stirred and the fitting are free of pollution and humidity. Poor stirring leads to smaller mechanical strength.

After casting the surface can made smooth by a short re melting with a hand held air heater.

Tests, especially mechanical test should be done min. after 24 hours.